With rapid advancements in semiconductor laser theory, materials, manufacturing processes, and packaging technologies, along with continuous improvements in power, efficiency, and lifespan, high-power semiconductor lasers are increasingly used as direct or pump light sources. These lasers are not only widely applied in laser processing, medical treatments, and display technologies but are also crucial in space optical communication, atmospheric sensing, LIDAR, and target recognition. High-power semiconductor lasers are pivotal in the development of several high-tech industries and represent a strategic competitive point among developed nations.

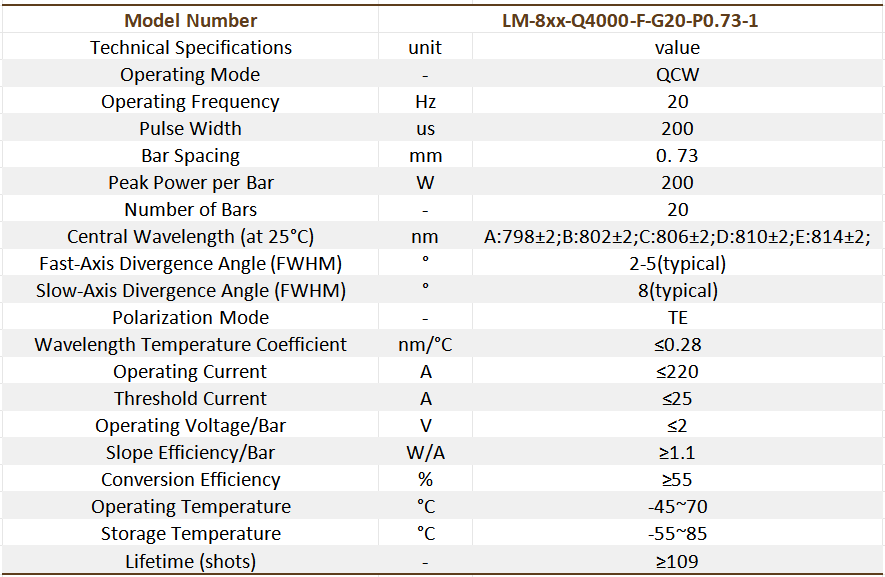

As core pump sources for solid-state and Fiber Lasers, semiconductor lasers exhibit a wavelength shift towards the red spectrum as working temperatures rise, typically by 0.2-0.3 nm/°C. This drift can lead to a mismatch between the emission lines of the LDs and the absorption lines of the solid gain media, decreasing the absorption coefficient and significantly reducing the laser output efficiency. Typically, complex temperature control systems are used to cool the lasers, which increase the system's size and power consumption. To meet the demands for miniaturization in applications like autonomous driving, laser ranging, and LIDAR, our company has introduced the multi-peak, conductively cooled stacked array series LM-8xx-Q4000-F-G20-P0.73-1. By expanding the number of LD emission lines, this product maintains stable absorption by the solid gain medium over a wide temperature range, reducing the pressure on temperature control systems and decreasing the laser's size and power consumption while ensuring high energy output. Leveraging advanced bare chip testing systems, vacuum coalescence bonding, interface material and fusion engineering, and transient thermal management, our company can achieve precise multi-peak control, high efficiency, advanced thermal management, and ensure long-term reliability and lifespan of our array products.

As a pump source for solid-state lasers, this innovative product was developed to expand the stable operating temperature range and simplify the laser’s thermal management system amidst trends towards semiconductor laser miniaturization. With our advanced bare chip testing system, we can precisely select bar chip wavelengths and power, allowing control over the product's wavelength range, spacing, and multiple controllable peaks (≥2 peaks), which broadens the operational temperature range and stabilizes pump absorption.

This product uses micro-optical lenses for fast-axis compression, tailoring the fast-axis divergence angle as per specific requirements to enhance beam quality. Our fast-axis online collimation system allows for real-time monitoring and adjustment during the compression process, ensuring that the spot profile adapts well to environmental temperature changes, with a variation of <12%.

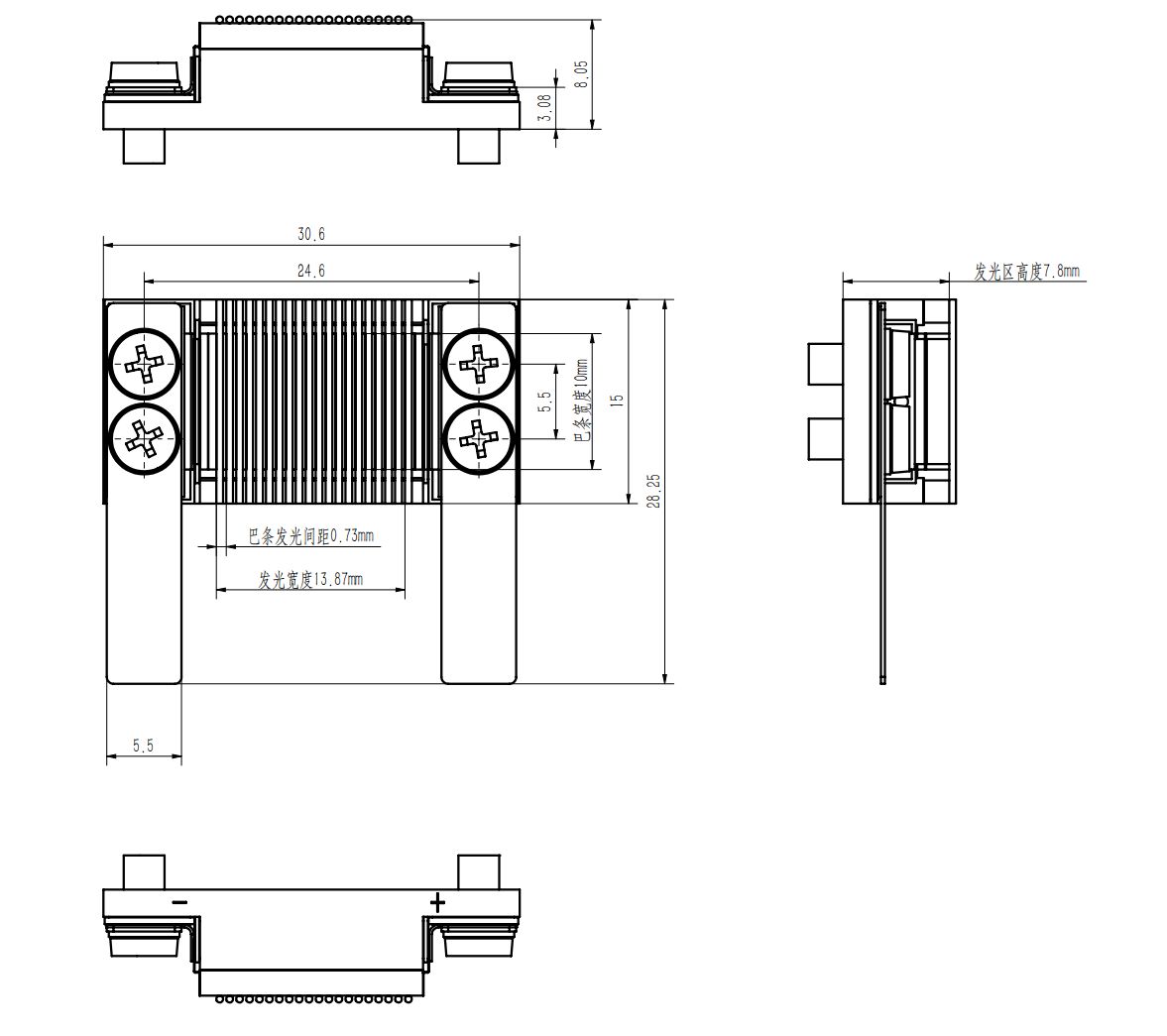

This product combines precision and practicality in its design. Characterized by its compact, streamlined appearance, it offers high flexibility in practical use. Its robust, durable structure and high-reliability components ensure long-term stable operation. The modular design allows for flexible customization to meet customer needs, including wavelength customization, emission spacing, and compression, making the product versatile and reliable.

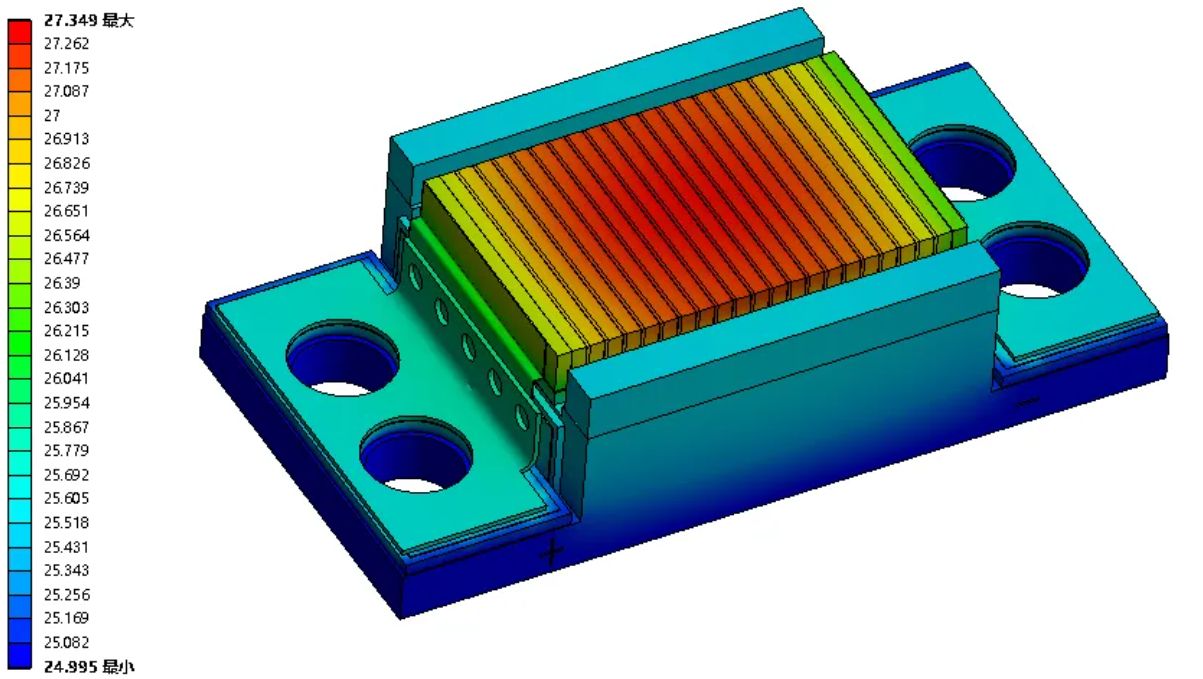

For the LM-8xx-Q4000-F-G20-P0.73-1 product, we use high thermal conductivity materials matched to the bar's CTE, ensuring material consistency and excellent heat dissipation. Finite element methods are employed to simulate and calculate the device's thermal field, effectively combining transient and steady-state thermal simulations to control temperature variations better.

This model uses traditional hard solder welding technology. Through process control, it ensures optimal heat dissipation within the set spacing, not only maintaining the product’s functionality but also ensuring its safety and durability.

The product features controllable multi-peak wavelengths, compact size, light weight, high electro-optical conversion efficiency, high reliability, and long lifespan. Our latest multi-peak semiconductor stacked array bar laser, as a multi-peak semiconductor laser, ensures that each wavelength peak is clearly visible. It can be precisely customized according to specific customer needs for wavelength requirements, spacing, bar count, and output power, demonstrating its flexible configuration features. The modular design adapts to a broad range of application environments, and different module combinations can meet various customer needs.

Lumimetric is committed to providing semiconductor lasers, laser Rangefinder Modules, and specialized laser detection and sensing light sources for niche markets. Our product range covers semiconductor lasers of various powers (405 nm to 1064 nm), line laser illumination systems, laser rangefinders (1 km to 50 km), high-energy solid-state laser sources (10mJ to 200mJ), continuous and pulsed fiber lasers, and precision to low-accuracy fiber optic gyros (32mm to 120mm). Our products are extensively used in LIDAR, laser communication, inertial navigation, remote sensing mapping, anti-terrorism and explosion protection, and laser lighting among other specialized industrial fields.

We focuses on research, product quality, and adheres to customer-first, innovation-first, and employee growth principles, positioning itself at the forefront of laser technology to seek new breakthroughs in industrial upgrades, aiming to become a global leader in specialized laser information fields.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China