In the realm of luxury and romance, diamonds reign supreme. These celestial stones embark on a remarkable journey, transforming from rough, hidden treasures into the crowning jewels of society's most coveted pieces. Central to this metamorphosis is the art of Diamond Cutting, a delicate balance of geometry and finesse that reveals each diamond's unique character and fire. Today, this traditional craft meets futuristic precision through the integration of advanced laser technology, setting new standards in beauty, quality, and sustainability.

In the meticulous world of diamond cutting, lasers represent a pinnacle of innovation. These beams of concentrated light slice through the hardest material known to man with unmatched precision, creating clean cuts and shapes that were once the sole domain of master craftsmen. But what does this technological advancement mean for your favorite diamond shapes? Let's delve into the refined world of laser-cut diamonds and explore how this modern technique is enhancing the beauty and allure of ten classic cuts.

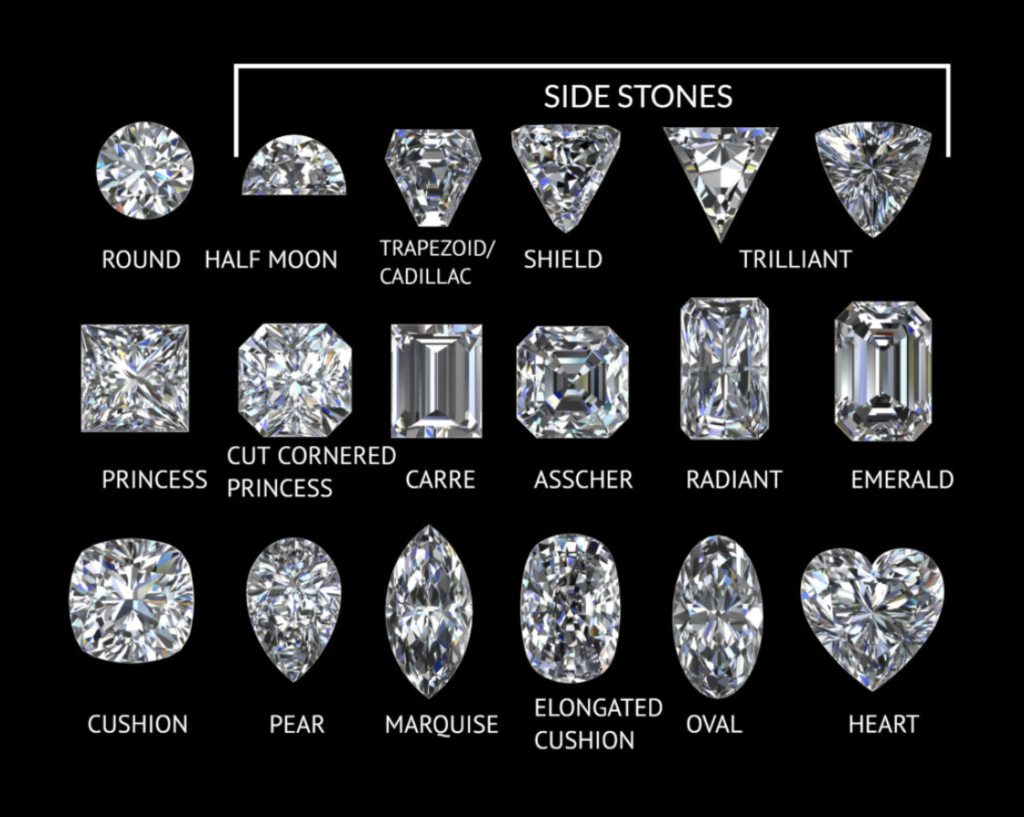

The round brilliant cut, a symbol of endless elegance, benefits immensely from laser precision. This technology ensures exacting symmetry across all 58 facets, optimizing the stone's reflective qualities and unleashing a spectacle of light and brilliance unmatched by less precise cutting methods (Shankar, 2015).

For the oval cut, lasers are indispensable in sculpting its perfect elliptical shape and achieving the ideal facet alignment. This precision prevents the undesirable 'bow-tie effect,' ensuring a balanced distribution of light and a brilliance that rivals the classic round cut (Zhang et al., 2021).

The modern princess cut, with its sharp angles and contemporary appeal, demands absolute accuracy during cutting. Laser technology meticulously crafts its distinct square shape, safeguarding against chipping and ensuring each facet meets with geometric perfection, resulting in a captivating play of light (Zhang et al., 2019).

The cushion cut, reminiscent of old-world glamour, receives a fresh breath of life with laser cutting. This technology enhances the cut's large facets and rounded corners, maximizing light dispersion within the stone and producing an intense radiance and unique, soft glow (Ke et al., 2021).

The emerald cut requires a masterful touch to preserve its open table and highlight the stone's clarity. Lasers assist in creating the cut's step-like facets with precision, reducing the risk of chipping and ensuring a clean, mirror-like effect that exudes sophistication (Cao et al., 2021).

Crafting the pear cut's singular teardrop shape is an art form, balancing symmetry and proportion. Laser precision is crucial in shaping the stone's rounded curves and pointed tip, ensuring a harmonious silhouette that captures the heart.

The Asscher cut, celebrated for its mesmerizing depth, relies on laser technology to perfect its complex x-shaped pattern, creating a captivating hall-of-mirrors effect. Each step facet is laser-cut with precision, contributing to its vintage charm and contemporary appeal.

The radiant cut, a harmonious blend of other styles, achieves its fiery brilliance through the strategic alignment of its facets, made possible by laser precision. This cut represents a fusion of tradition and innovation, offering spectacular light performance.

Selecting a diamond is a deeply personal experience, influenced by the stone's technical attributes and the emotional resonance it evokes. Whether you're drawn to the timeless elegance of the round brilliant, the avant-garde allure of the princess cut, or the unique personality of the pear shape, your choice is a reflection of your inner self. As enduring symbols of resilience and beauty, these gems serve as daily reminders of your own strength and brilliance.

In this radiant selection, laser technology plays a pivotal role, enhancing the diamond cutter's artistry. This synergy of human skill and advanced technology not only brings forth the intrinsic beauty of each diamond but also honors the sustainable and ethical practices increasingly valued in our modern world. As we adorn ourselves with these sparkling treasures, we also celebrate the innovation and conscientious craftsmanship that continue to shape the future of luxury.

Lumimetric has provided light sources and technical support to many users in the field of laser cut diamonds, and today has compiled a list of the more common questions about laser gemstone cutting.

1. How did they cut diamonds before lasers?/How were diamond cut before lasers?

2. Challenge in Diamond cutting and sawing

3. What are the advantages of laser cutting compared with Traditional Diamond Cutting?

4.How Laser Technology Refines 10 Classic Diamond Cuts?

References:

Shankar, N. (2015). "Cool Laser for Cutting Diamonds." Laser Technik Journal, 12(3), 33-37.

Zhang, J., Han, L., Zhang, J., Li, G., Xu, J., Yan, Y., & Sun, T. (2019). "Finite Element Analysis of the Effect of Tool Rake Angle on Brittle-to-Ductile Transition in Diamond Cutting of Silicon." The International Journal of Advanced Manufacturing Technology, 103, 1503-1516

Ke, J., Chen, X., Liu, C., Zhang, J., Yang, H., & Xu, J. (2021). "Enhancing the Ductile Machinability of Single-Crystal Silicon by Laser-Assisted Diamond Cutting." The International Journal of Advanced Manufacturing Technology, 114, 241-252.

Cao, Z., Zong, W., He, C., Huang, J., Liu, W., & Wei, Z. (2021). "Transient Temperature Monitoring and Safe Cutting Speed Exploration in Diamond Turning of PBX Surrogates." The International Journal of Advanced Manufacturing Technology, 118, 89-100.

We hereby declare that certain images displayed on our website are collected from the internet and Wikipedia for the purposes of furthering education and sharing information. We respect the intellectual property rights of all original creators. These images are used with no intention of commercial gain.

If you believe that any content used infringes upon your copyrights, please contact us. We are more than willing to take appropriate measures, including removing the images or providing proper attribution, to ensure compliance with intellectual property laws and regulations. Our aim is to maintain a platform that is rich in content, fair, and respectful of others' intellectual property rights.

Please reach out to us via the following contact method, email: sales@lumispot.cn. We commit to taking immediate action upon receipt of any notification and ensure 100% cooperation in resolving any such issues.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China